Our team of over 30 designers, engineers and computer scientists offers a diverse range of technical experience, allowing us to tackle a wide array of challenges. We utilize small teams, comprised primarily of senior staff, who are given broad spans of control and accountability. These highly experienced and nimble teams allow us to avoid potentially risky or fruitless explorations, and focus on the most promising opportunities. We understand how many small pieces of incremental risk can quickly add up to an unacceptable level of risk. We are able to streamline our clients’ product development experience with a predictable and prudent schedule, while maintaining their original vision and desired market impact.

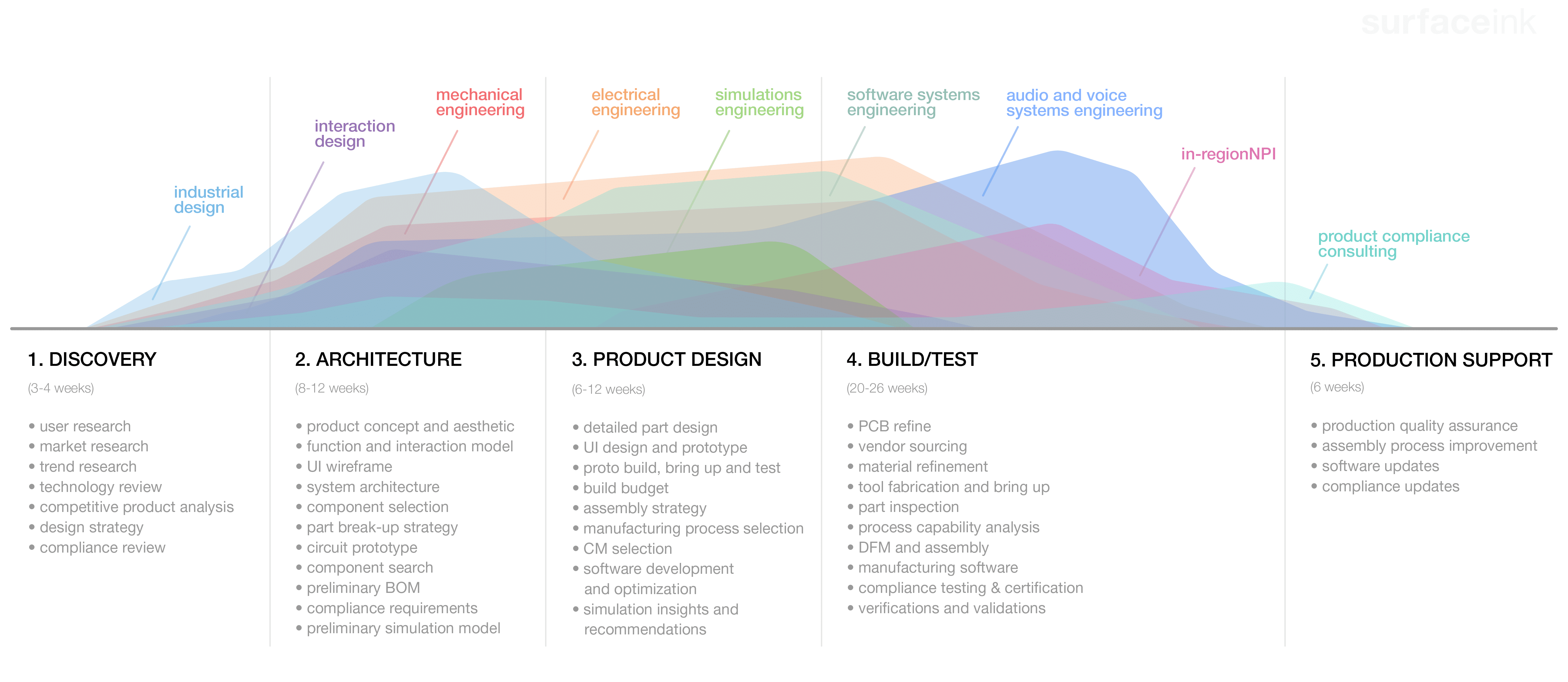

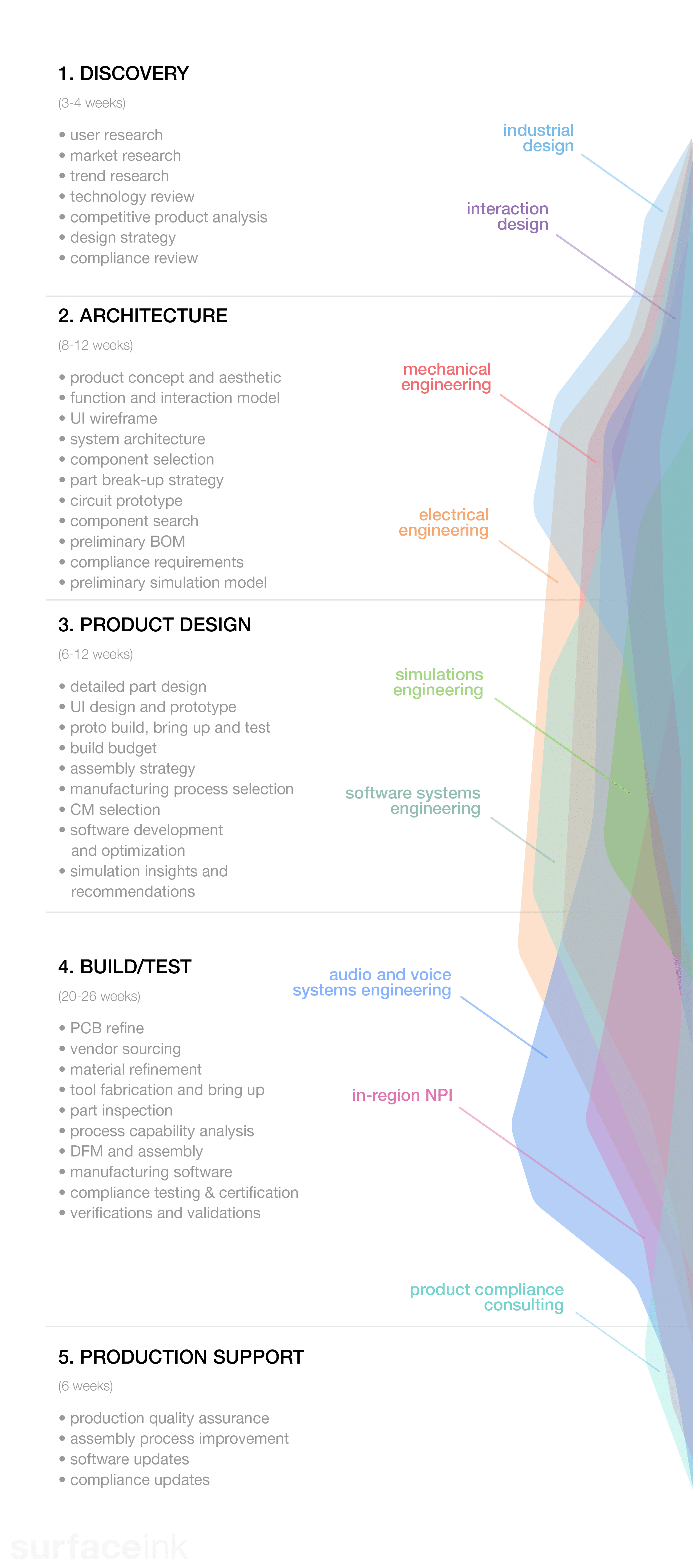

product development process

our services

industrial design

creating the product concept, user experience and visual expression of the brand

- product concept

- form & detail development

- physical interaction

- ergonomics

- colors, materials, & finishes

- product graphics

ui/ux design

creating digital interface solutions between people and devices

- digital device interface strategy

- user experience mapping

- wireframing

- GUI design

mechanical engineering

solving structural and design integration challenges

- assembly strategy

- thermal architecture

- complex mechanism design

- structural analysis

- design for manufacturing (DFM)

- master modeling & complex surfacing

electrical engineering

developing the physical hardware platform from cutting edge consumer electronics products

- system architecture and optimization

- detailed design and analysis

- performance and cost optimization tradeoffs

- technical feasibility and risk mitigation

- prototype and pre-production validation

- component selection, schematic capture and PCB layout

- tight collaboration with multi-disciplinary team counterparts

- expertise in electronics miniaturization

- regulatory and compliance support

- production contract manufacturing transition support

software systems development

software for hardware (IoT)

- firmware

- middleware

- apps

- HMI

- connectivity

- machine learning

- back-end development

- cloud applications

audio and voice systems engineering

optimizing sound for various product form factors

- acoustics

- audio electronics

- DSP integration

- component level test

- production line test

product compliance consulting

navigating the regulatory and compliance maze with confidence

- architect a clear strategy & attack compliance early

- integrate the compliance mindset into your product development process

- safety

- compatibility

- interoperability

- sustainability

- accelerate testing & certification schedules

- prepare factories for audits & production ramps

- leverage our experience to fulfill your product visions

in-region NPI

supporting new production introduction

- vendor sourcing, qualification and management

- build activities support (EVT, DVT)

- tool bring-up

- production quality assurance

- assembly process improvement

- multi-process expertise (plastics, metals, glass, and ceramics)