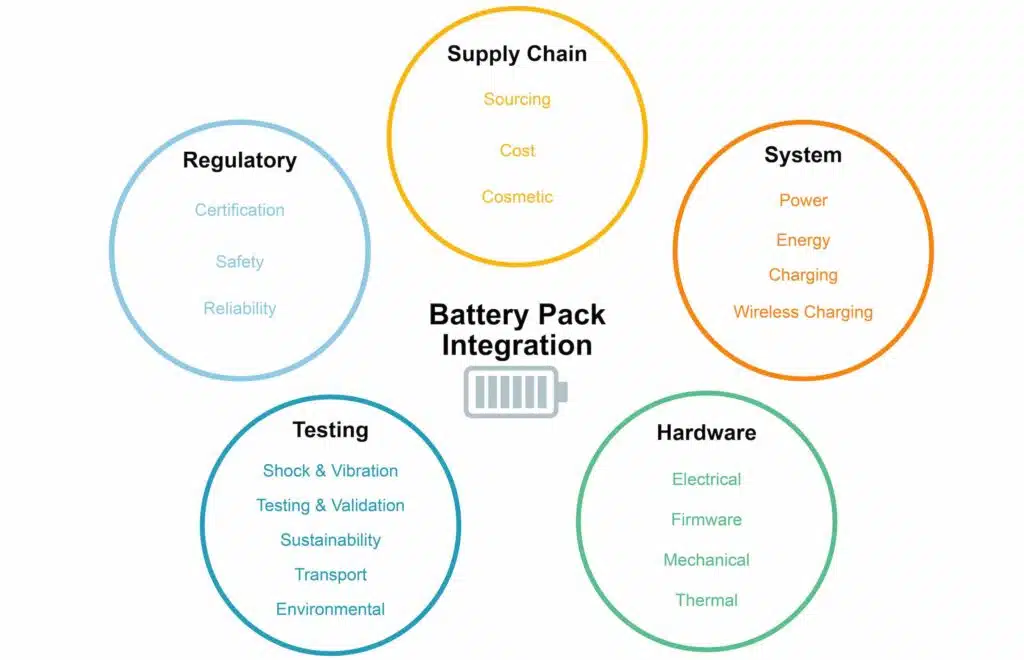

Surfaceink has provided battery integration across a wide range of products, including full design, mechanical integration, power management, thermal management, and mechanical packaging.

smart ring – full design integration

- Micro form factor and unique complex geometry

- Full custom battery

- Matching common batteries across multiple SKUs

- Battery safety

- Large quantity (1000s) qualification/pilot builds – Science and development teams

- Managing thermals during assembly and attachment

- Inductive charging with base station

- Vendor sourcing – multi-sourced with small/med production volumes

- Enclosed to protect from water ingress

- Reliability and environmental testing

wireless earbuds – mechanical integration, power management

- Ultra-small form factor in an in-ear consumer wearable

- Constant use micro power scenario involving dual radios

- Rechargeable battery in micro form factor

- Battery safety

- Managing thermals during assembly and attachment

- Vendor sourcing

- Semi-custom Battery

- Recharging from Battery charge case accessory

- Reliability and environmental testing

smart eyeglasses – mechanical integration, power management

- Ultra-small form factor

- Precise power management

- Battery in a consumer wearable

smart personal air purifier – mechanical integration, power management

- Small form factor – body worn device

- Off the shelf micro battery – small volumes

- Battery safety

- Vendor sourcing

- Large quantity qualification/proto builds (100s) – science and development teams

- Constant use micro power scenario involving high power sensor

- Recharging from custom charge cable/dock

- Reliability and environmental testing

digital dice – mechanical integration, power management

- Space saving OTS pouch battery

- Innovative wireless charging and watchdog power states for consumer toy

vr controllers – mechanical integration, power management

- Swapping a replaceable AA alkaline battery with a rechargeable, safe, and powerful battery pack

smart watch – mechanical integration, power management

- Space saving (shape, size, and construction) steel can battery for replaceable smart watch battery

vr headset strap – mechanical integration, power management

- Complex geometry and safety considerations on a head worn consumer product

specialized drone – mechanical integration, power management, thermal management

- Extreme power density, charge/discharge requirements in a harsh industrial environment

specialized drone – mechanical integration, power management, thermal management

- Extreme power/weight quick-swap battery pack, with harsh charge/discharge in a tactical environment

face calling device – battery mechanical packaging

- Space optimization for new pouch batteries and 18650 housings

- Battery protection from physical damage and thermal damage

- Design documentation for mass production

- Technical coordination with customer and supplier battery team

- Establishing goals and documenting progress

- Flexible to changing goals from various departments

- Designs that meet international regulations for shipping and safety

- Design of battery pouch, adhesives, protective films, plastic fire rated parts, battery changes over lifetime, clearances