no coaster needed

This glassware delivers a coaster less glass, so there are no water rings or stains or need to wipe down surfaces.

early-stage development – proving the concept

Surfaceink was engaged to help develop prototypes to validate proprietary technology. We performed endless tests around adsorption of the material, evaporation of water, volume of material, volume of condensing water, surface area and design of ceramic, temperature, pressure, and humidity. These initial reference points helped us further validate the proof-of-concept across multiple

services provided

Product Architecture

Product Surfacing

Industrial Design

Material Research

Prototyping / Testing

Mechanical Engineering

Manufacturing Support

Manufacturing Sourcing for Mass Production

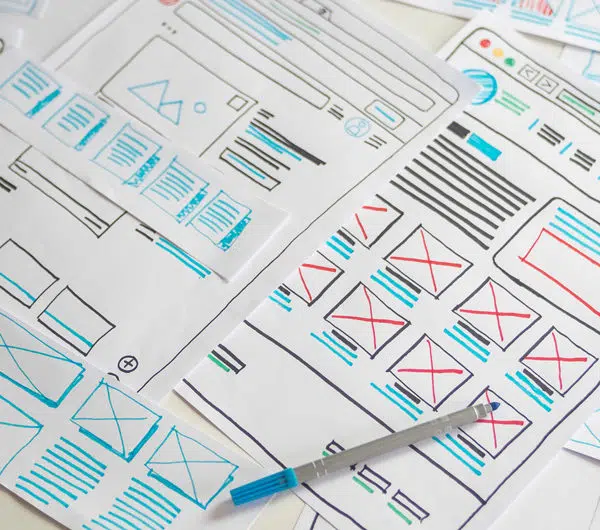

design

sketch exploration

Our design team explored combinations of different glasses and ring/coaster forms – overall size, proportion, height, shape, and placement.

market research

To evaluate the current market, we sampled a variety of glassware from different stores and compared forms, shapes, sizing, and weight.

CAD exploration

It was essential to view the concepts rendered in the correct materials to properly compare and evaluate.

testing

clean testing

It was vital that the ceramic be tested with range of staining ingredients, then cleaned with different methods from dishwasher to bleach.

temperature & humidity testing

To evaluate the ceramic volume needed to adsorb condensation from glasses, we simulated different combinations of weather temperatures and humidity levels inside a scientific humidity chamber.

ceramic ring evaluations

To maintain quality assurance for the mass production it was imperative to note any imperfections found on the initial batch.

UV fixtures

The unique assembly of this product required a new development, iterations, and testing of UV fixtures that would center align all the parts while