Here are just a few examples of how Surfaceink has applied innovation to early stage product development.

NOTE: Due to the nature of the work and NDAs, this is only a top level recap of how our product ideation and engineering teams have collaborated with our clients.

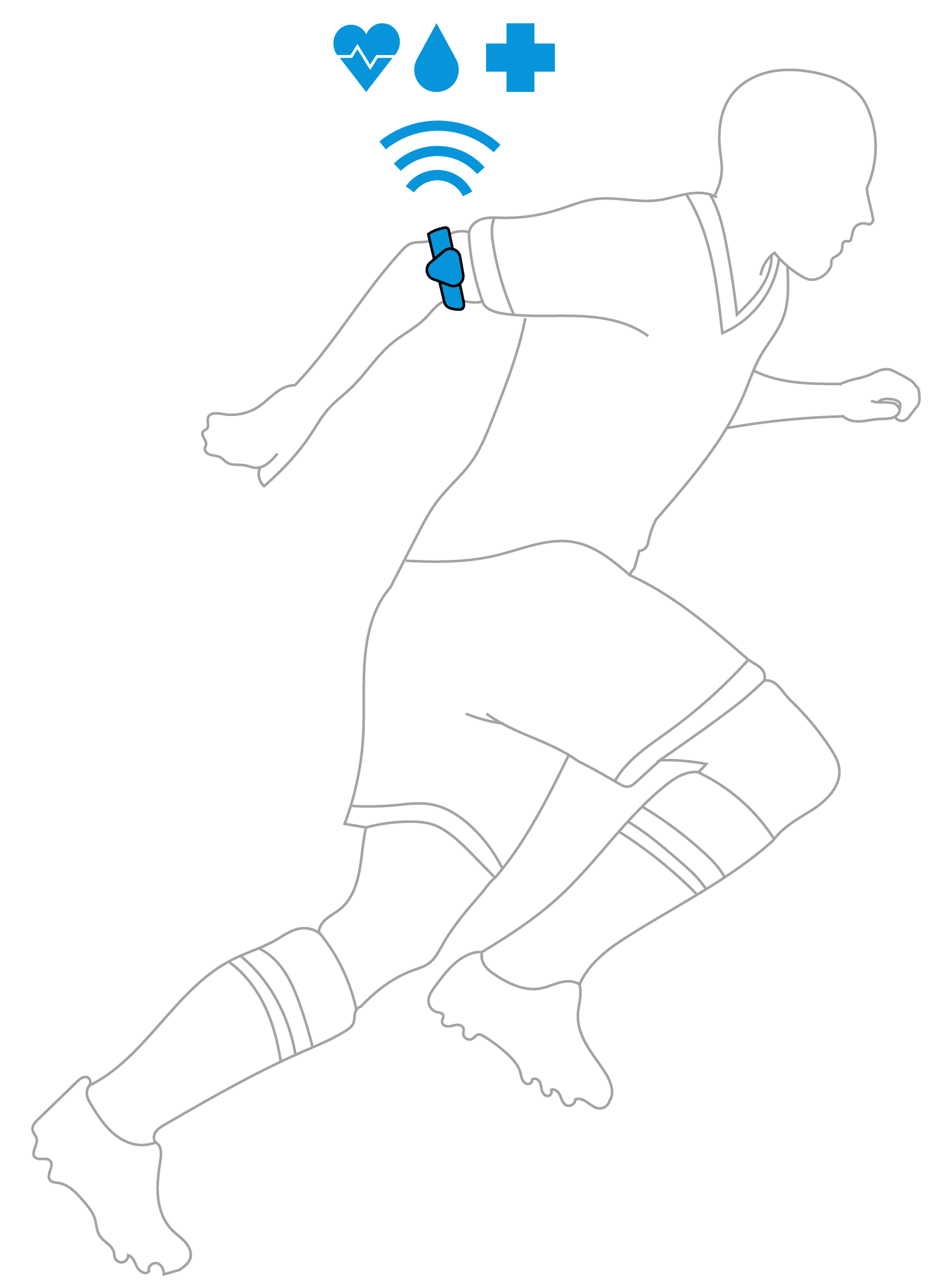

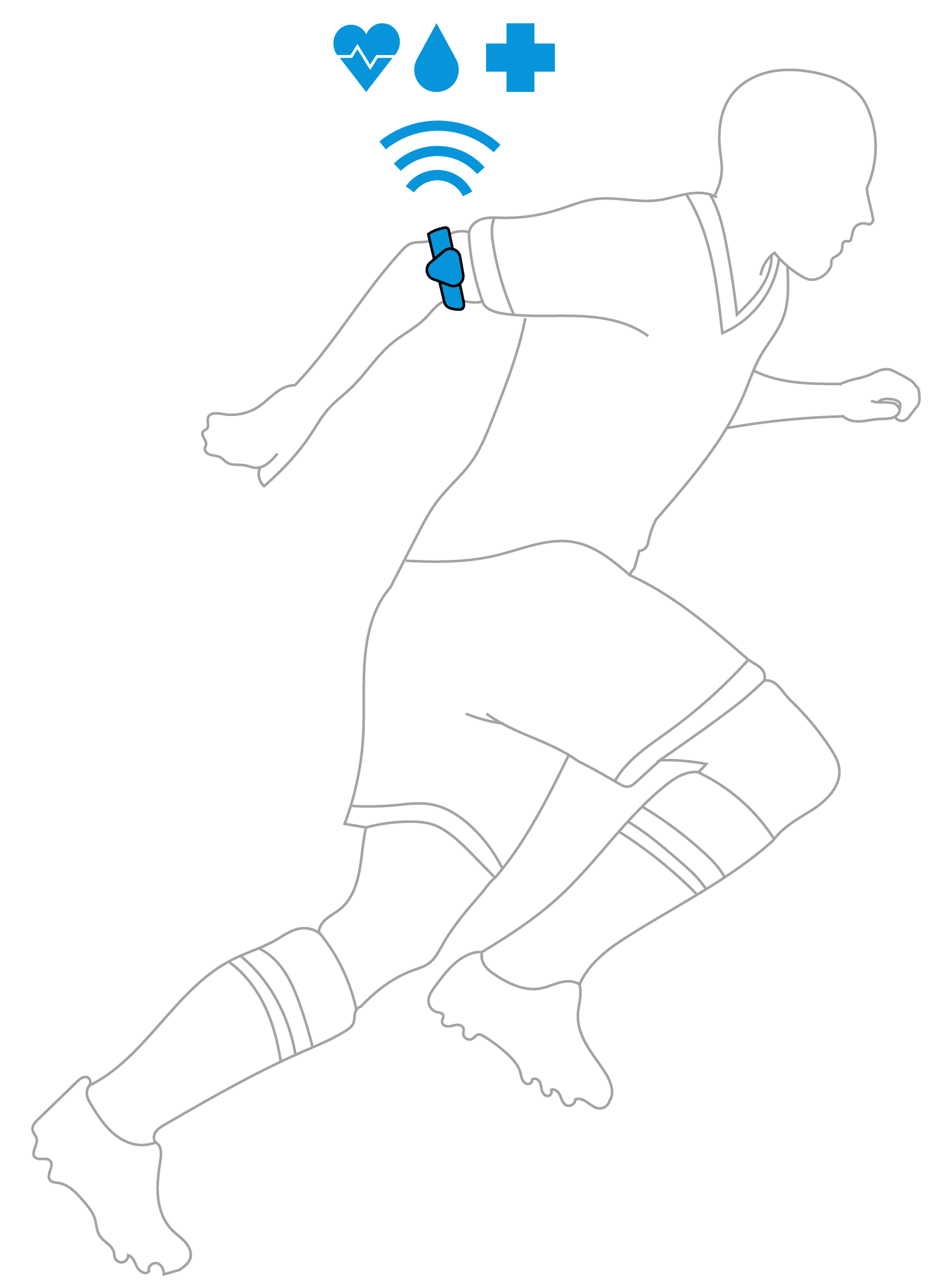

Wearable Device System Designed for Competitive Amateur Team Sports

The Idea: Wearable to track athletic on-field performance and provide real time feedback (i.e. tracking & monitoring) and analytics to trainers and coaches Route-running accuracy, speed, hydration, etc.

The Innovation: Applying multiple tracking technologies, radio with on-the-field infrastructure system – wearables provide data (location & biometrics) that gets relayed to sideline hub, then uploaded to cloud. This was achieved by using a single tracking and RF technology (UWB: Ultra-Wide Band) vs. multiple bandwidths.

Our Role: Proof of concept with 60 devices and complete portable field system, testing, ME, EE (hardware chip, module, & dev kit selection), & FW/SW.

Wearable Device System Designed for Competitive Amateur Team Sports

The Idea: Wearable to track athletic on-field performance and provide real time feedback (i.e. tracking & monitoring) and analytics to trainers and coaches Route-running accuracy, speed, hydration, etc.

The Innovation: Applying multiple tracking technologies, radio with on-the-field infrastructure system – wearables provide data (location & biometrics) that gets relayed to sideline hub, then uploaded to cloud. This was achieved by using a single tracking and RF technology (UWB: Ultra-Wide Band) vs. multiple bandwidths.

Our Role: Proof of concept with 60 devices and complete portable field system, testing, ME, EE (hardware chip, module, & dev kit selection), & FW/SW.

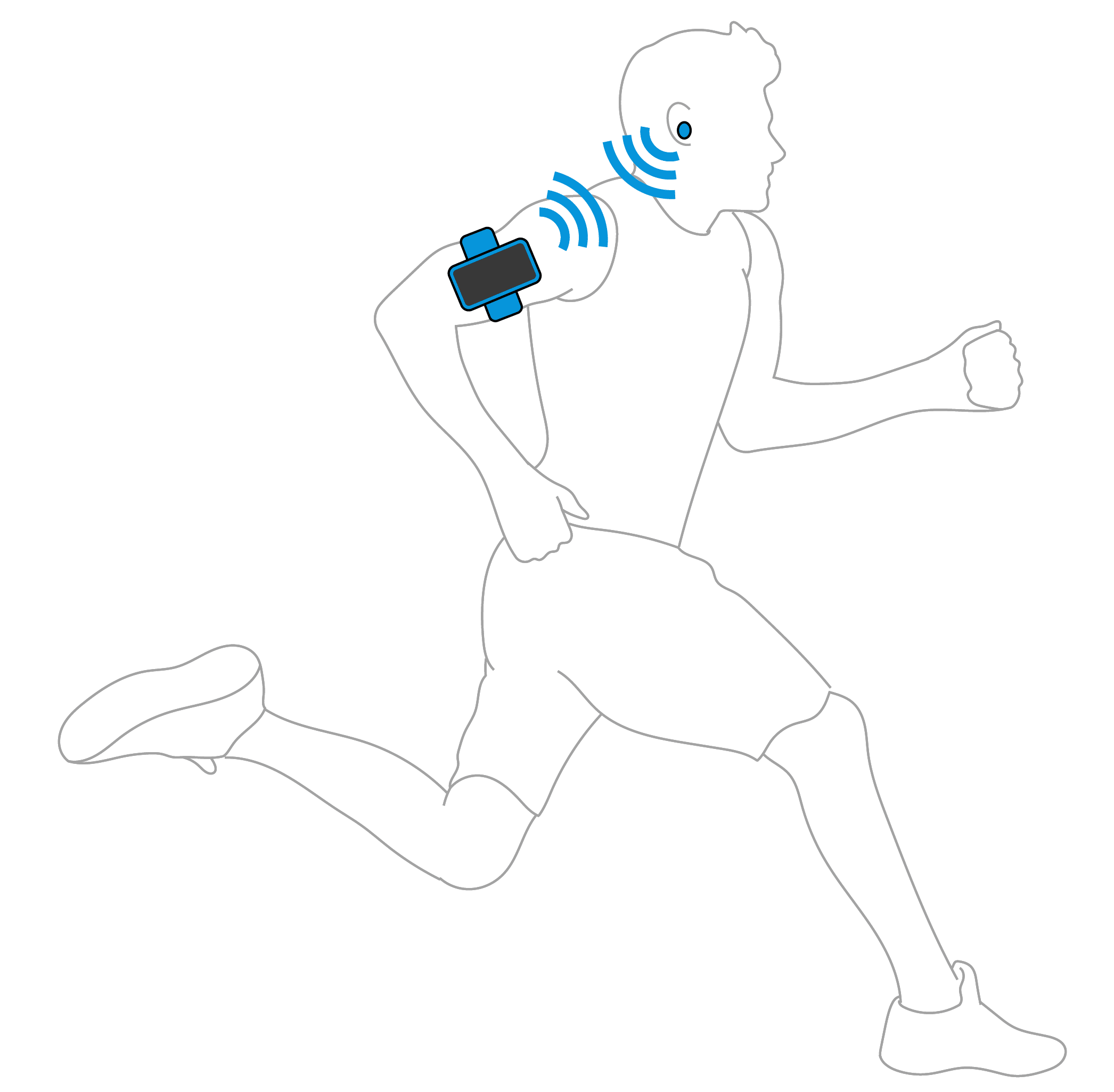

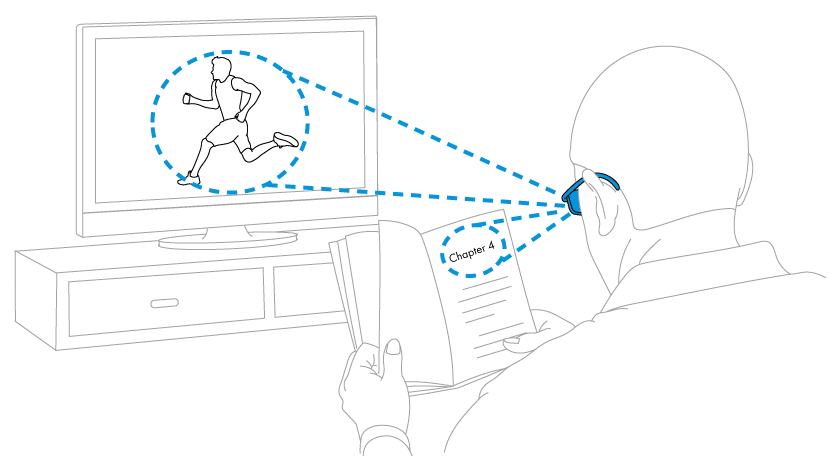

True Wireless Bluetooth Earbuds

The Idea: The first wireless Bluetooth earphones (earbud system)

The Innovation: Designing truly wireless (non-tethered) set of earbuds using Bluetooth Classic.

Our Role: Proof of concept, audio engineering (sound & performance quality), EE, ME, FW/SW, hardware development, RF BLE system, system design & integration through to NPI tool release. We helped innovate a patentable over-the-body creeping wave approach to maintaining a signal around the obstacle of the human body to enable one of the first untethered Bluetooth earbuds.

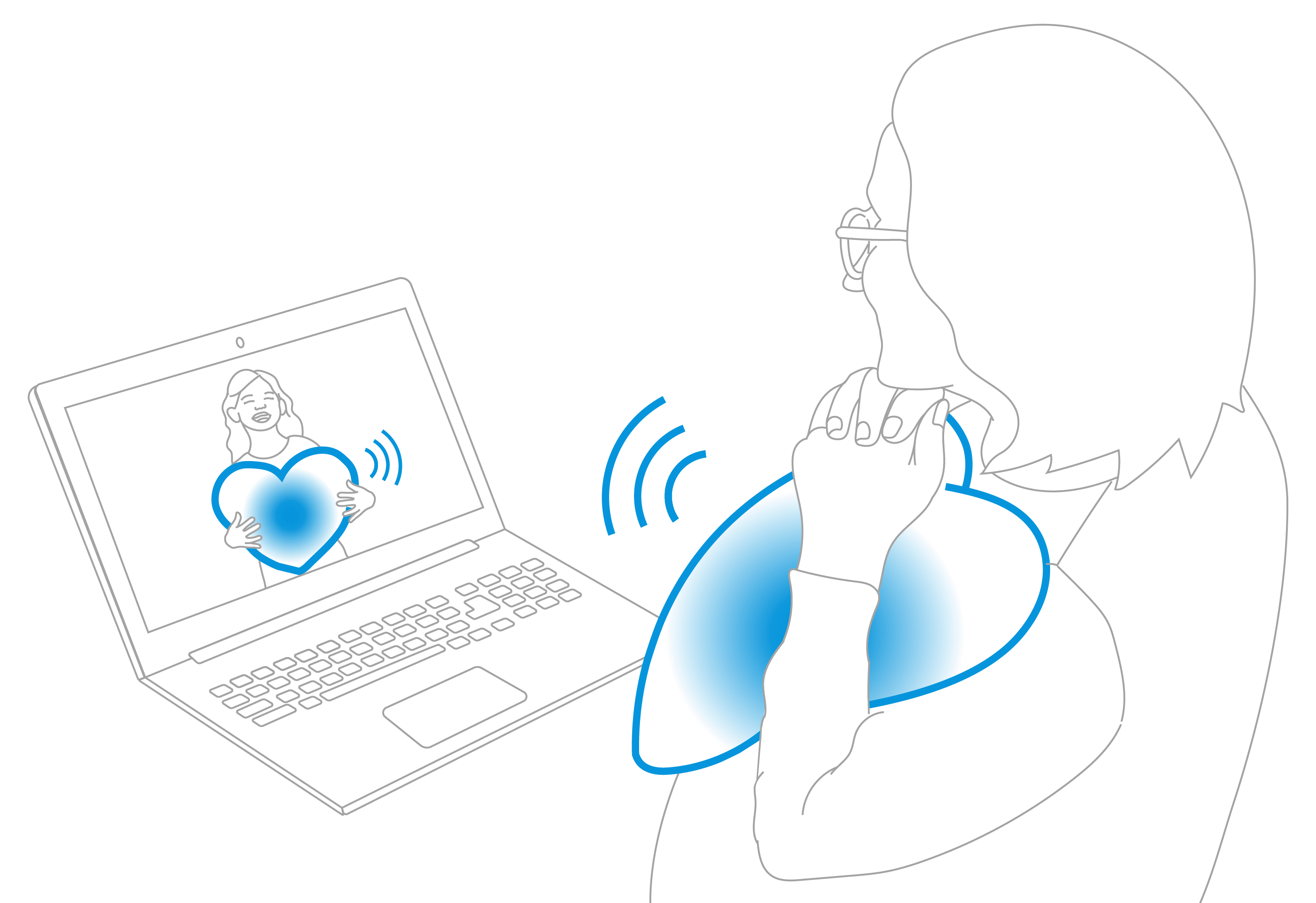

Remote Haptic Device

The Idea: Miniaturized electronic soft goods to simulate human touch interactions between remote participants.

The Innovation: Brainstorming and prototyping a wide range of tactile interaction modalities, including patterning heat and cold sensations using nichrome wire, Peltier devices, and ferrofluidic heat transfer, as well as creating dynamic pressure sensations using soft materials inflated by synchronized piezo microblowers.

Our Role: All of this was eventually wrapped into a battery-powered hand-held unit with live BLE communication to remote participants. We did all EE, ME, and firmware for the device, created a demo mobile app, and designed the backend communication protocol.

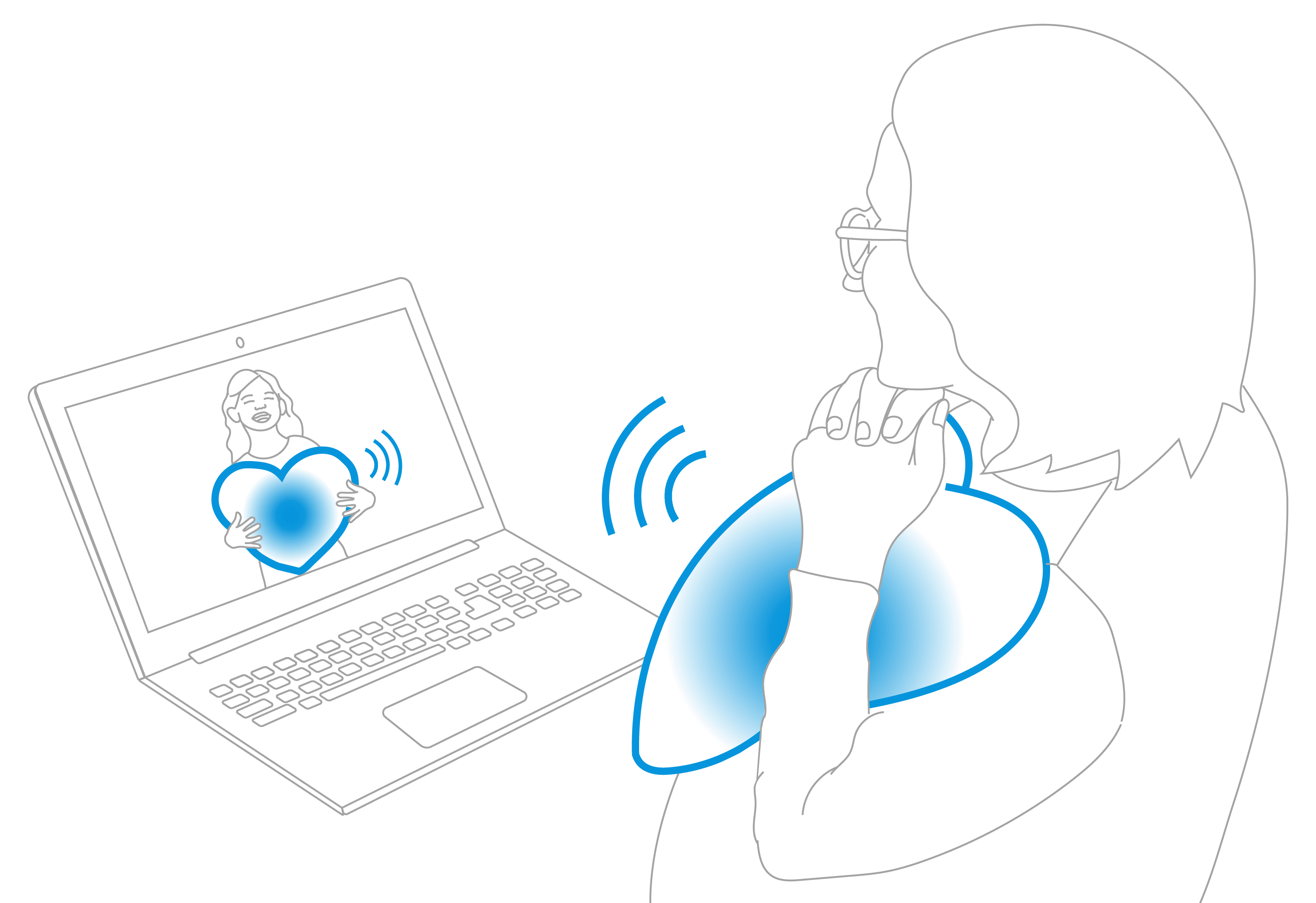

Remote Haptic Device

The Idea: Miniaturized electronic soft goods to simulate human touch interactions between remote participants.

The Innovation: Brainstorming and prototyping a wide range of tactile interaction modalities, including patterning heat and cold sensations using nichrome wire, Peltier devices, and ferrofluidic heat transfer, as well as creating dynamic pressure sensations using soft materials inflated by synchronized piezo microblowers.

Our Role: All of this was eventually wrapped into a battery-powered hand-held unit with live BLE communication to remote participants. We did all EE, ME, and firmware for the device, created a demo mobile app, and designed the backend communication protocol.

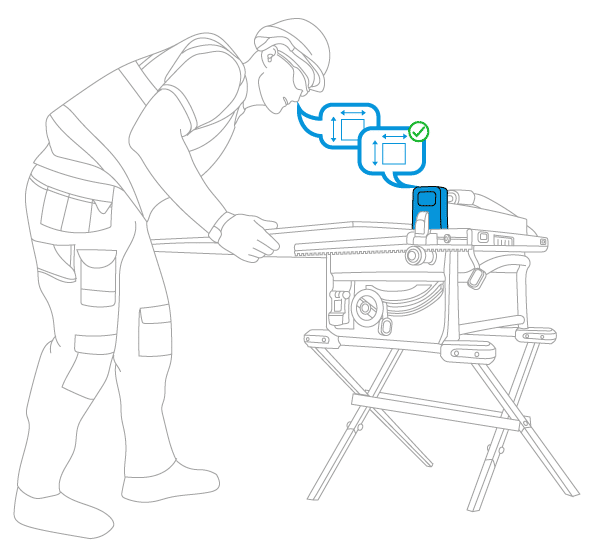

Smart Construction Tools

The Idea: Voice-enabled concept device that interoperates with an existing family of networked construction equipment.

The Innovation: Client concept was to enable voice-based annotation, calculation, and data-sharing across networked job site equipment to streamline sharing of information between hands-on workers and fabrication personnel. We guided them through the process of creating a fully enabled device that met their vision in an extremely short timeframe. We went from concept to multiple working PoC devices in 10 weeks.

Our Role: Complete product. We did everything from EE/ME to the full software stack, including on-device firmware and voice service application, as well as all cloud services needed for the demo functionality: Skill development, backend storage, and data sharing paradigm.

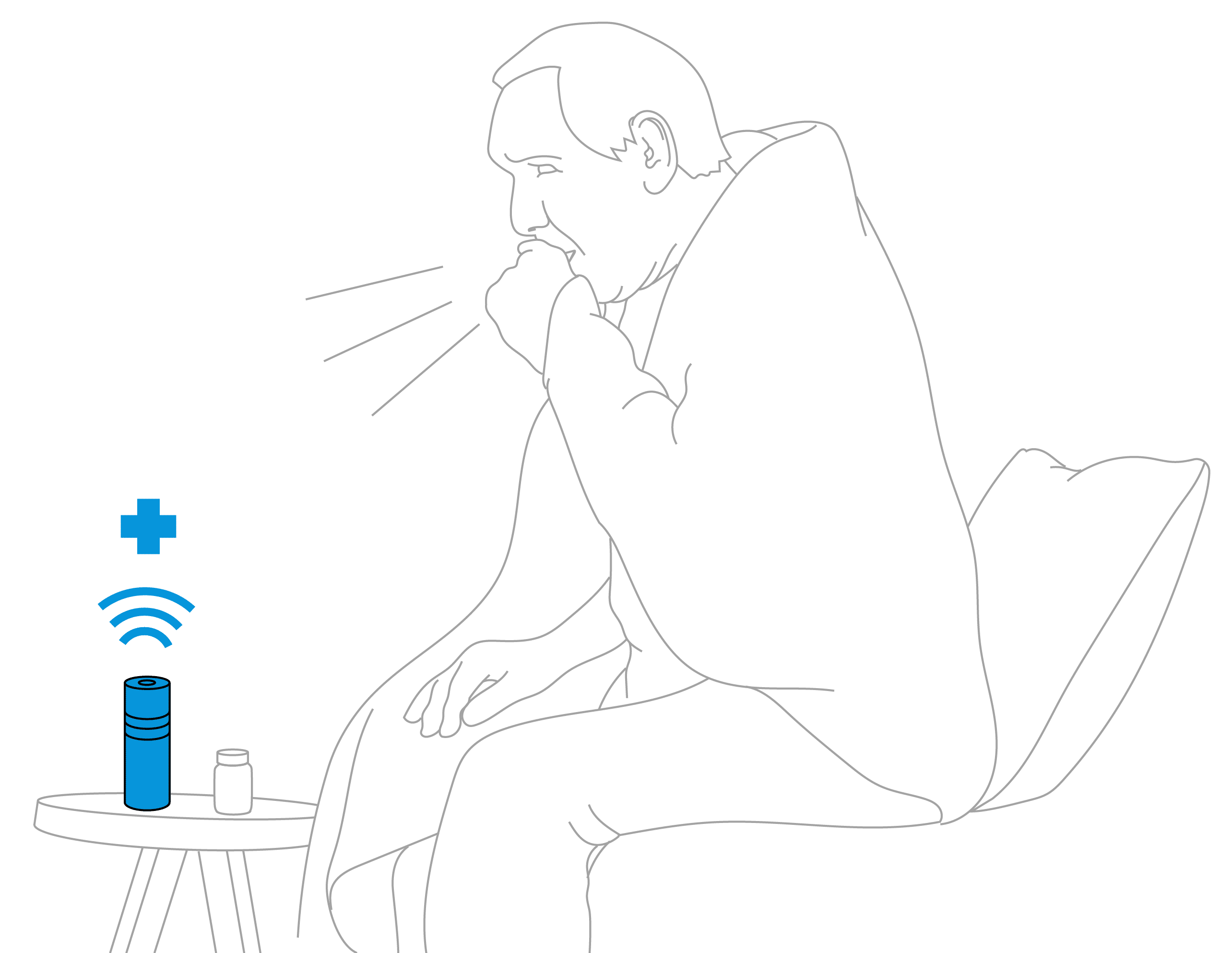

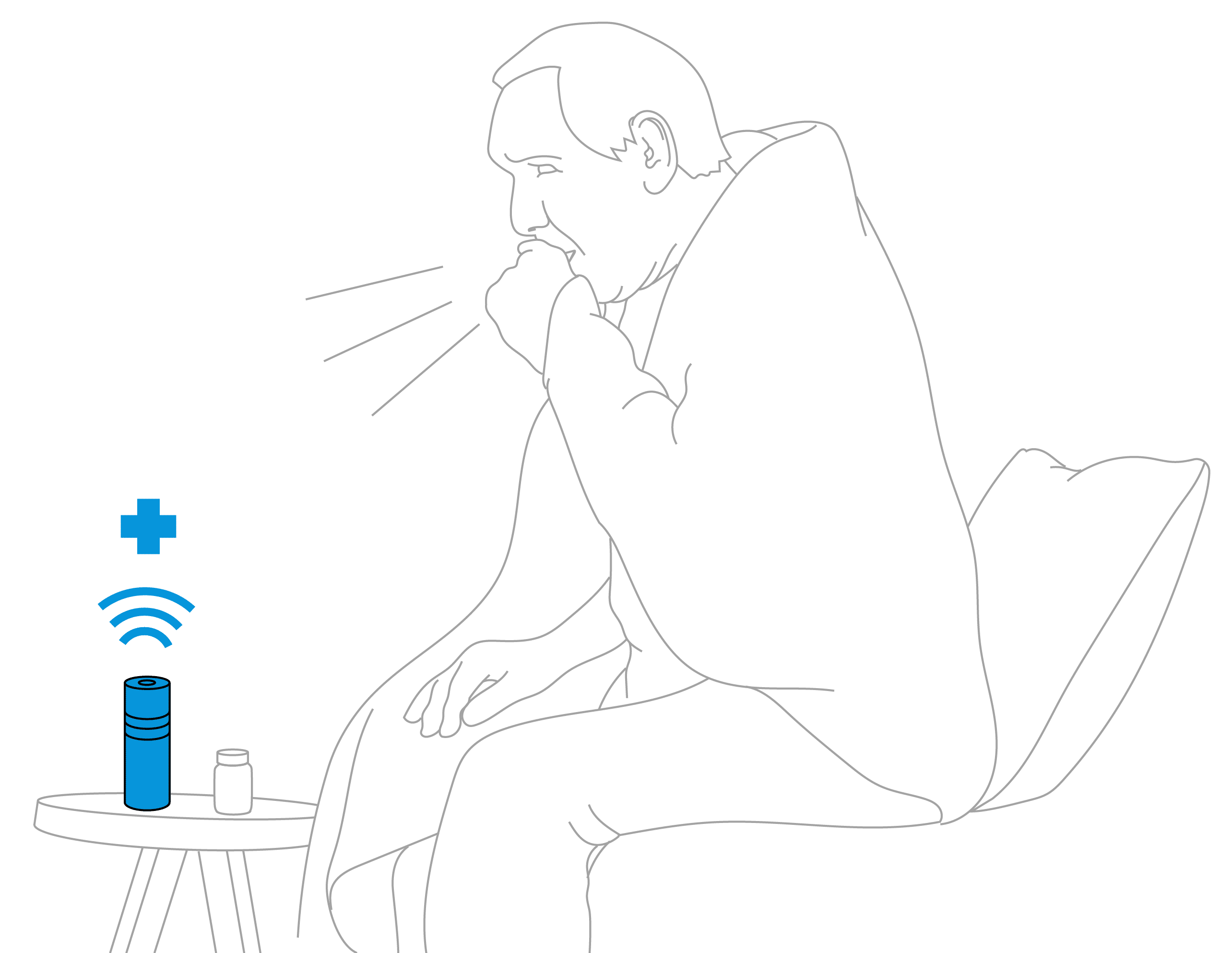

Smart Speaker Health Diagnostic Device

The Idea: A smart speaker that monitors health of patient both passively and/or actively;

The Innovation: Leverage current technology products (i.e. smart speakers and Cloud Voice Services) and combine with client backend algorithms for medical purposes. software coding uses cloud & local; far-field voice-capture for speech recognition, analysis, and noise cancellation without content corruption. Multi-stream human-to-human, human-to-machine, and filtered raw audio.

Our Role: Proof of concept, skill development, investigate raw mic samples rate and implementation, ME, FW/SW.

Smart Speaker Health Diagnostic Device

The Idea: A smart speaker that monitors health of patient both passively and/or actively;

The Innovation: Leverage current technology products (i.e. smart speakers and Cloud Voice Services) and combine with client backend algorithms for medical purposes. software coding uses cloud & local; far-field voice-capture for speech recognition, analysis, and noise cancellation without content corruption. Multi-stream human-to-human, human-to-machine, and filtered raw audio.

Our Role: Proof of concept, AVS skill development, investigate raw mic samples rate and implementation, ME, FW/SW.

Adjustable Corrective Lenses

The Idea: A tunable optical lens for variable diopters would enable use cases and facililitate better user experiences than bifocals or progressive lenses.

The Innovation: Miniaturization of the mechanism including the full motor gear box 10:1 in a volume less than a cubic inch with micron-level resolution while maintaining Lb. level holding force to achieve the ability to position the optical lenses to adjust the focal length.

The miniaturization of the mechanism was achieved through the unique methodology of creating a micro-sheet 3D-formed part via chemical etching.

Our Role: Architect proof of concept, ME, Optomechanical Engineering, mechanism design.

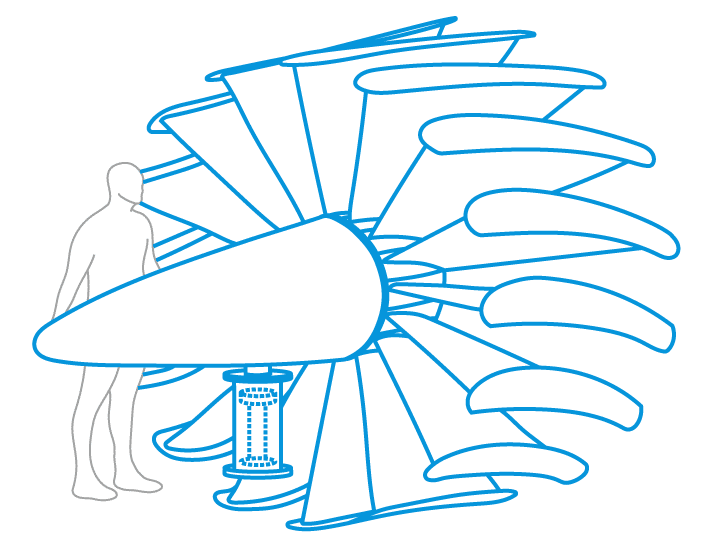

Low Speed Wind Turbine

The Idea: Wind turbines kill and injure wildlife. Develop a wind turbine blades and housing design for low speed – high torque in a novel blade orientation departing from the traditional windmill/airplane propeller configuration.

The Innovation: Low speed, high efficiency, aerodynamically silent power generation.

Our Role: 3D CAD design, proto documentation package, identify/select/support prototype manufacturing, prototype for early validation & test data (prototype Low RPM Wind Turbine), foil design, material selection (carbon fiber blades)

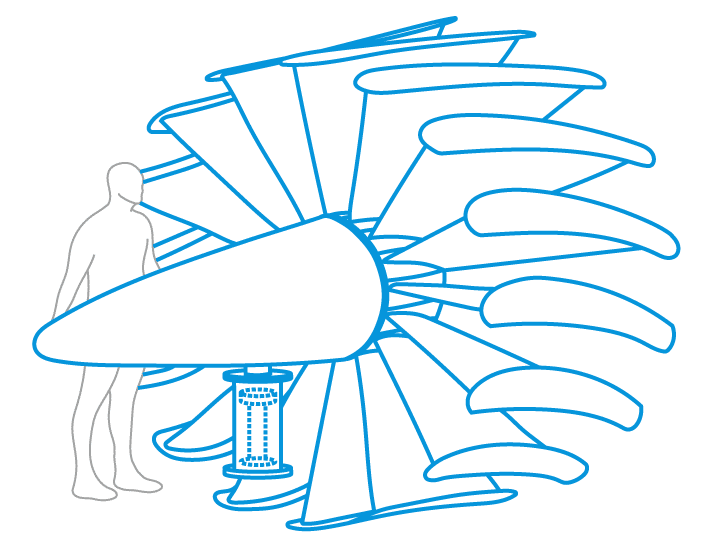

Low Speed Wind Turbine

The Idea: Wind turbines kill and injure wildlife. Develop a wind turbine blades and housing design for low speed – high torque in a novel blade orientation departing from the traditional windmill/airplane propeller configuration.

The Innovation: Low speed, high efficiency, aerodynamically silent power generation.

Our Role: 3D CAD design, proto documentation package, identify/select/support prototype manufacturing, prototype for early validation & test data (prototype Low RPM Wind Turbine), foil design, material selection (carbon fiber blades)